So you’ve heard my opinion on building a house ad infinitum over the past few years and now, it’s probably the turn of the builder to have a say. Months of pestering Stephen to write a blog hasn’t had any effect and so it’s going to be an interview format instead. I’ll try not to colour it too much with my own thoughts, but given that, when I listened back to the recording, it was largely me talking, that could be hard. I’m no Graham Norton by any means.

I’d lined up the kind of questions I thought would get me some interesting answers, and illuminate something of the process of the build from the point of view of the builder.

I get started: “Why did you take on a half built house when lots of other builders had turned me down?”

“I thought, ‘that looks easy, I’ll do that'” said Stephen.

I tried again, “What were the low points or problems with the build” I asked.

“None really, it was pretty straightforward. Your house should have been the easiest house in the world to build”

Oh…. This was shaping up to be a rather tedious blog where I come out looking like a total numptie. I tried another tack.

We spoke about the best builds he’d done and he reeled off a list: “That one on the island in Oban Bay for sale, a big house in Easdale, the one in Benderloch, (that’s for sale too at the moment for 1.3 million I’ll send you the particulars…) my own, twice”.

I’d already used the joke that the new house in Oban Bay is for sale because they got his final bill so I leave it and press him on the question, “But which one is the best thing you’ve built? Is it your own house?”

“No way, of course not. You know yourself, building your own house is really awful”

“Really?”, I ask, amazed, “even for a builder?”

Stephen built his own house between dealing with all the other projects he was working on “I’d try and be done by two and then come and work on the house until eleven, and sometimes four in the morning towards the end”

But did he never get to see his family? “The kids would be in bed by seven and I’d go back out again to the build”

Stephen has been building for 25 years, starting when he was 16. I do a quick calculation on my fingers “Forty one! same as me!” I say triumphantly and ask why he decided to go into building.

“I didn’t have any qualifications, my dad and uncle were joiners, it was the thing to do, it was in the blood”

I think back to my early career. I didn’t have my first proper job until I was 27 after a year out either side of university and a PhD. But why did I become a biologist? Because, well, my parents were biologists, I even went to the same university as my parents. My sister took the same route too. I certainly didn’t have a better reason for choosing my own career.

We move onto the subject of working with people. He has certainly had worse clients than me. Much worse as it turns out.

“Sometimes I can’t actually speak to them,” he said “and then I just send the boys in and stay away. Once when someone was really bad I had a Polish guy working for me and I just sent him in and told him to pretend he didn’t speak English”.

Now I can tell you, that I have certainly put the hours in to try and be good to work with. I was pretty desperate at the time Stephen appeared on the scene, I’d just called every builder in the phone book from Fort William to Oban, even the one who friends suggested I didn’t touch with a barge-pole. In fact the whole past year can he summarized as a major Stephen charm offensive: getting stuff to site on time, attempting (and failing) not to be too in-your-face, paying bills really quickly, being generally charming. Why do you think I wrote so many nice blogs about Stephen? In fact I don’t recall a charm offensive as prolonged as this since I met the long-suffering husband.

I ask something about what I’m like to work with, hoping to elicit a positive comment. Nothing.

So how does he decide whether to take on a job or not? “I make up my mind about whether I can work with someone within the first few seconds. And if I don’t think I can work with them I don’t take on the job”

It’s a bit awkward asking about yourself so I leave the obvious question hanging and ask “What’s the first thing you remember about my build?”

“It was the panicked answerphone message I got on the Friday. You just sounded really desperate” he chuckles.

He brightens further with chat about the highlights of the build which all revolve around the incompetencies of Builder#4 who I will name Phil for the purposes of this blog.

“The highlight? – It’s got to be Phil’s caravan and tent and saw” he said in answer to the question and collapsed in laughter. “And then there’s the fridge full of beer. You know a builder’s good when he gets his priorities right, and the fridge of beer was the first thing to appear on site”

He went on “Then there was the business card – ‘landscape, Joinery, Deliveries'” I start to feel uncomfortable remembering all the horrors of my poor decision making.

“But the best has got to be the day the boy burnt the sausages for breakfast and they all packed up and went home.” He said. I wilt.

Stephen described, with glee, the time sheets his team put in when they started on the interior work after Phil had left.

sorting Phil’s Shambles —– 8 hours.

“He really looked like he was doing it for the first time” said Stephen. “And when someone is that bad, it makes everyone else look really really good”

“It was funny when they didn’t arrive until 1130am one day when the rugby was on, saying they were on a landscaping job til late the night before, and went straight for a snooze in the caravan. They were still in there when the boys left that night.”

Stephen pauses for a moment to chuckle, “the next morning when they emerged they went straight to the Holly Tree to watch the rugby and, when they got back, they said there wasn’t much point getting started so headed straight back to the central belt”

At this point I had been transported back to the full horror of the Phil episode. Aren’t we done yet? I wonder.

“Seeing you hit rock bottom”

Eh what? That doesn’t seem like a highlight.

But appeared that it was.

“Phil really broke you, you were totally defeated” said Stephen: twice, just in case I didn’t hear the first time.

“Actually,” I say, feeling the need to defend myself, and point out my resilience and stoicism, “the worst bit was having to talk to you about it to sort everything out”.

(And that’s a fact. That bit was truly and utterly awful)

When things were bad, I didn’t even talk to the long-suffering husband about it. I didn’t want to. It was all too dreadful. I’d get home, after the two-hour drive back to Glasgow with the 90s club classics turned right up in an attempt to drive out the house-build ‘drag-me-down’ vibes with the ecstatic feel of a rave in a field, and Husband would pass me the wine and put on the iplayer. Everything would suddenly be right with the world.

“You can’t build a house without wine” said Stephen, evidently from plenty of bitter personal experience “Can you imagine what it would be like without the wine? You need wine. God, we’d all be dead without the wine.”

I told him the story of the sacking of Phil, done, as I do many things, to minimize conflict and just get it done as painlessly as possible. I spent some considerable time that day getting Phil to accept that he couldn’t finish the job and to take all his equipment and caravan off site. (Throughout this awkward conversation the, already rather physically imposing man, towered above me. “Shall we sit down” I said, Phil sat on a step ladder on top of a pile of boards “are you going to sit down?” He’d asked “no I think I’ll stand” I said). Once everything was offsite except the ruddy saw and the ruddy fridge (minus the beer unfortunately) I followed up with a phone call to finish the job.

Yes I suppose it did rather break me, I admit.

“It’s hard sacking someone” says Stephen pensively.

“Yup. I’m finding it a bit difficult to think about it even now” I say.

The interview had become a house-building therapy session. “It must have been hard,” said Stephen, “There’s probably some wall gone up there”.

“Why did I make such a useless decision to go with Phil instead of you for the interior work?” I wail.

“You just need to go with your gut instinct but you probably didn’t do that” said Stephen sympathetically.

I wander off into thinking about a management training I was at a few years ago. We were discussing personality and how people make decisions. According to the psychologists, people like me usually take decisions intuitively and instinctively (tell me something I don’t know…), but when they are under heavy stress they can start to take decisions in a different way, trying to use more rational approaches, which usually means they make bad decisions. I pull myself away from the looming cliff of introspection and back to the task in hand.

“Hold on Stephen. Who is the interviewer here?”

It seems that I’m not the only person Stephen has seen in a defeated slump. “People are usually like that when they come to me. The whole process of planning and building control does people in, it takes years and they just want the house built.”

And it’s not just the clients who can have a hard time. Later in our discussions Stephen tells me that even he can have a bad time at it. “Sometimes you get a job that really breaks you, you just have to tell yourself that it will be over soon and get on with it, but if it’s a house build, it can last a very long time.”

I ask if he liked reading the blogs I’d written about him. He brightened considerably, “I love it” he said. “People keep asking whether I’m builder #1 #2 #3or #4.”

According to Stephen, Lots of people around Oban read the blog, “the partner of your planning officer, he reads it.” He said (Oh….. I thought about the blog I wrote about our trip up to fort william to charm the planners and my toes curled gently under the table.)

“Everyone does.”

I do know that my building control officer reads it – he emailed me to say so after I’d written a blog about him (eliciting another slight curling of the toes)

The joy of writing about the build has been that Stephen has always been very blasé about what I write about him. I always sent the blogs to him to make sure he was happy. “I really don’t care what you write” he would say repeatedly “Say whatever you like.”

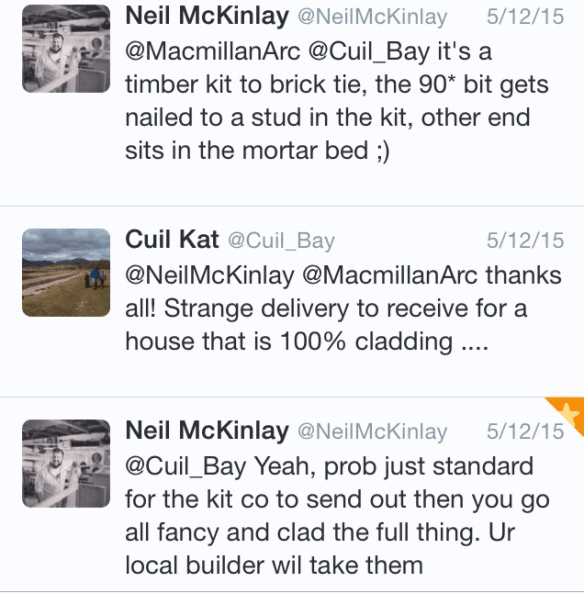

Once I mused, on Twitter, about the writers block I was suffering as a convenience of worrying about the builders reading it.

“Fire on, I’ve got my own blog ready for when the cheque clears” came back the response from Stephen.

And that was when the idea of a guest blog from the builder, and the architect, and anyone else who fancies sticking an oar in, came about.

And that was when the idea of a guest blog from the builder, and the architect, and anyone else who fancies sticking an oar in, came about.

And, of course, that is how I come to be interviewing Stephen.

Conscious that the product of the interview thus far hasn’t made me look particularly competent, I go fishing for something that could save my reputation. Was there anything I did right?

“When you filmed the cow in the next door neighbour’s garden, that was funny”. Stephen was referring to the morning when Jamie the farmer came over while we were talking about what to do about the porch.

“You’ve caused me a load of @&$@ing grief Kat” said Jamie. Oh dear, I thought, what could it be; the articulated lorries coming down the ridiculously small road and trying to turn in his drive? The piles of detritus all over the landscape related to my house build? The gaping potholes that seem to get bigger every time another truck, transit or lorry zooms down the track? Apparently not, it was the time lapse video I’d made of me and a few friends trying to build a shed and which gave a view of the neighbour’s garden. “The neighbours saw it and there was one of my @&$@ing cows in there eating their hedging plants. They were straight on the phone to me last night” he said. We all fell about laughing.

Funny, Stephen, yes. But IT DOESN’T ANSWER THE QUESTION. was there anything I did right during the build?

“Well you’d actually make a very good project manager” he said eventually, when pressed.

Really? In what way?

“In the way of being really good at organising people, finding someone who knows how to do the job and getting them to do it”.

Well, knock me over with a feather. I didn’t expect that to come out of the interview. My job here was done.

There was one last question I really had to ask. One that had been bothering me since the start of the interview.

“Seeing as my house should have been the easiest house in the world to build, and nothing in it was a problem for you, did my epic charm offensive have any effect or was it just totally wasted effort?”

Hummmmm. As I suspected, it seemed that all my efforts to be charming and good to work with were rather unnecessary, and probably went unnoticed. I looked rather downcast.

“It didn’t go unnoticed.” said Stephen “The boys appreciated the chocolates, well, the ones that didn’t fall in the mud.”

At Christmas I’d made special whisky chocolates for all the people on site – the filling was melted white chocolate mixed with Glenmorangie. There was an awful lot of whisky in each of those chocolates and everyone got four in a home-made box. (Well not everyone, two boxes fell in a huge puddle when I got out of the car so Eddie the tiler and I scoffed all of those after we’d rinsed them under the tap). You don’t get much more charming than that, but no-one ever mentioned it

But whether or not the charm offensive was necessary, effective, or even noticed, It probably was essential for my own entertainment and well-being during the build. When you’re building a house, you think about it every single day. Every day. And that means you need to think about the builder every day. This can become somewhat debilitating if you are having difficulties with your builder. Thinking about Phil always made me irritable, downcast and miserable to be around.

Very early on I accepted that I was just going to have to think about Stephen quite a lot, so I might as well see it as one of the good things about building my house. Especially when the good things are rather few and far between, consisting of writing the blog and inventing new ways of making splashbacks and shower screens, and nothing much else.

Stephen is very aware of the huge importance that he and his team have in the lives of people building a house.

“We become a major part of people’s lives, we recognise that” he says “and working with interesting people is always part of the attractions of a job”.

There were just so many absolutely hateful, tedious or just downright soul-sapping tasks that I had to find a way to make myself want to do. Who wants to spend a sunny Saturday choosing bathroom stuff? Or having to give list after list of things to do to the builder. It’s just not fun. There are about a million things I could think of that I’d rather be doing than building this house. For some reason, actually finishing the house was never much of a motivating factor in itself, I had come to terms that I would be building the house well into the distant future and was simply looking for ways of making the process more bearable.

I have found, over the past few years, ways of persuading myself to do tasks I don’t want to. I’ve actually got quite good at it now, I can even fill in a reporting spreadsheet, if my life depends on it.

I’ve found that it’s people that motivate me, not tasks. So I always need to have a person that I’m doing the task for. If the task isn’t for a specific person then I need to imagine one. For example, when I write some interpretation, a leaflet or a press release at work I need to have my audience clearly in mind in the shape of a real person. And I can only tidy and clean the house if there’s someone coming for dinner (I sometimes plan a dinner party simply because the house needs a tidy). A deadline, real or invented, always helps too.

When it came to the house, the charm offensive has certainly kept me occupied and entertained, and it has given me another reason for writing the blog, providing me with a muse from time to time (who evidently liked reading blogs about himself). But importantly it provided the motivation for doing all those painfully annoying things you need to get done to build a house. Like getting some essential component of the house to site by a certain date, or hassling Scotframe yet again to do what they said they would.

In fact, the whole fun of building the house, pretty much the only good bits, have all been the bits where I’ve worked with brilliant and effective people. Not just Stephen, but also Stephen the stonemason, Jamie who installed the MVHR, and Stephen’s team, especially Eddie who was the only person who didn’t seem to object to having his photo taken; Stuart the builder who did the foundations, and numerous others, including the architects and Tom (kitchen) and Jake (wood) who I’ve known since University. On the other side, the worst bits are when I’ve worked with difficult people: Phil being the only one that springs to mind.

It’s only because of those people that, despite the problems and difficulties, building Sula has actually turned out to be a hugely enriching experience.

We planted Scotia Seeds wildflower seeds. Flowering lawn and pond edge mix. Also wet meadow for the wet bits. Somehow I madly did it months and months before the fencing was done (see blog) do it is now pockmarked with cow footprints on all the ‘lawn’. Which is annoying.

We planted Scotia Seeds wildflower seeds. Flowering lawn and pond edge mix. Also wet meadow for the wet bits. Somehow I madly did it months and months before the fencing was done (see blog) do it is now pockmarked with cow footprints on all the ‘lawn’. Which is annoying.

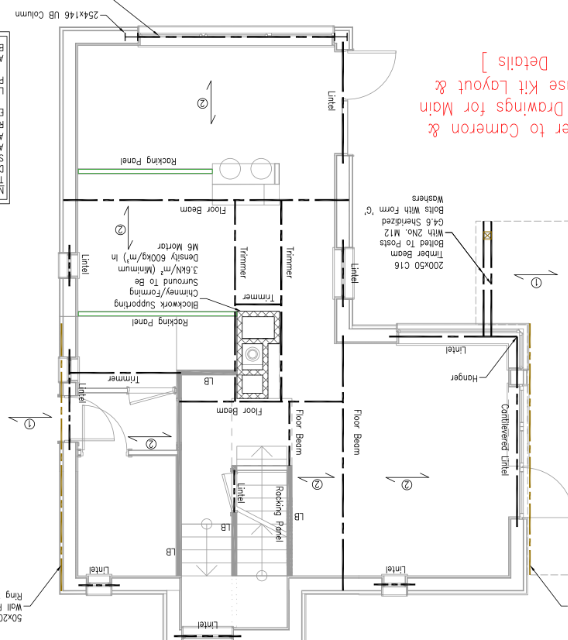

Theres now a hanger on one side but the beam is still held up by nails on the other….

Theres now a hanger on one side but the beam is still held up by nails on the other….

How hard can it be…?

How hard can it be…?